Proper storage of tools and equipment in industries is crucial for maintaining efficiency, safety, and longevity of equipment. Whether it’s heavy machinery, precision tools, or commercial refrigeration equipment, how these items are stored can significantly impact operations and costs.

This article explores the importance of implementing effective storage practices in industrial settings.

Importance of Organized Storage

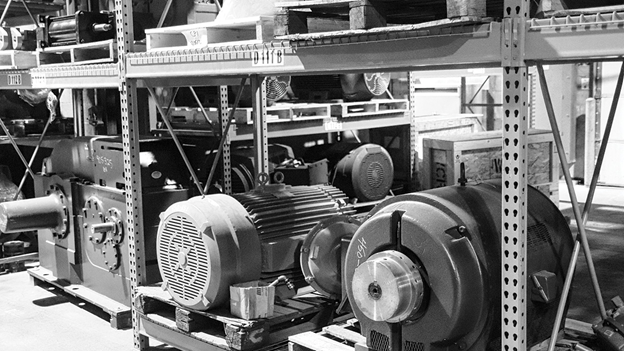

In any industry, organization is key. Imagine a workshop where tools are scattered, and equipment is haphazardly stored. Not only does this create confusion and waste time, but it can also lead to accidents. Properly organized storage systems ensure that every tool and piece of equipment has its designated place, reducing the risk of injury and enhancing workflow efficiency.

Protection from Damage

Tools and equipment are often significant investments for industries. Without proper storage, they are vulnerable to damage from environmental factors such as moisture, dust, and temperature fluctuations. For instance, sensitive equipment like heating oil machinery or commercial refrigeration equipment can malfunction if not stored correctly, leading to costly repairs or replacements.

Safety First

Safety is paramount in any workplace. Improperly stored tools can pose serious hazards. Sharp tools left lying around can cause cuts or punctures, while heavy equipment stored precariously may result in accidents.

By implementing secure storage solutions, industries prioritize the safety of their workers, fostering a secure work environment.

Maximizing Efficiency

Efficiency is the backbone of industrial success. A well-organized storage system ensures that tools and equipment are readily accessible when needed. This minimizes downtime spent searching for misplaced items and allows employees to focus on productive tasks.

In industries where timing is critical, such as those relying on heating oil deliveries, efficient storage practices directly contribute to operational efficiency.

Extending Equipment Lifespan

Proper storage not only protects tools and equipment from physical damage but also extends their lifespan. Machinery and tools that are stored in dry, clean environments experience less wear and tear. This reduces maintenance costs and prolongs the usefulness of equipment, ultimately saving industries money in the long run.

Compliance and Accountability

Many industries are subject to regulatory standards regarding equipment storage and maintenance. Proper storage practices help companies comply with these regulations, avoiding potential fines or legal issues.

Additionally, organized storage facilitates inventory management and accountability, ensuring that tools are accounted for and maintained according to industry standards.

Environmental Considerations

Industries often operate in diverse environmental conditions. Proper storage of tools and equipment takes into account these factors to mitigate risks and ensure operational continuity. For instance, sensitive equipment like heating oil systems and commercial refrigeration units require stable environments to function optimally.

By storing them in controlled conditions, industries minimize the impact of temperature fluctuations and humidity, thereby preserving equipment performance and reliability.

Conclusion

In conclusion, the importance of proper storage of tools and equipment for industries cannot be overstated. From enhancing safety and efficiency to protecting investments and ensuring compliance, organized storage systems play a critical role in industrial operations.

By prioritizing effective storage practices, industries not only safeguard their equipment but also optimize their overall productivity and profitability.